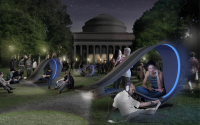

Soft Rocker with its Own Power Generation

By Christine Ethier (Energy Trace)

A very creative and forward thinking team at MIT have developed an interesting chair. It's a very cool looking chair in many people's opinion and many claim it's comfortable as well. It's also wonderful that the chairs are available outside where there are limited places to sit in such comfort. However, this is all beside the point. One of the main impetuses behind the design and promotion of the soft rocker is to make some of the power needs of the community the responsibility of its members, reducing reliance on non-renewable resources and simultaneously involving the consuming population in the provision of its own power needs. Each time someone pulls on the handle of a soft rocker to readjust the chair's orientation to the sun, that person participates in the solution. In power terms, the idea makes a small contribution to living off the grid; in empowering terms, this idea and others like it, may be the key to saving the planet.

The design is at once simple and deceptively complex. The technique that makes the design possible was originally pioneered under the name ZipShape by SchindlerSalmeron in Germany. Here it is extended into a multi-sheet system that allowed the designers Sheila Kennedy, Professor of Architecture at MIT and team members Phil Seaton, Shevy Rockcastle, Jungmin Nam, Kate Bogunschutz, and James Baylessto produce the continuous, custom-formed 29' curve that comprises the chair.

Across the landscape of any available space and carefully set for the correct local latitude, these chairs provide the power to both recharge devices like cell phones and computers and to radiate attractive lighting in hours of darkness.

Bravo to the team at MIT! The soft rocker may actually provide an answer to that nagging question "But what can I do about it?

Images reproduced with the permission of team member Phil Seaton. More are provided on his site www.phil-seaton.com under the heading 'soft rocker'.

TopBrandenburg: Expanded 8.5 megawatt biogas plant from Greenline in operation

Substrate mix consists mainly of slurry and energy crops

The biogas plant in Vettin, located in the municipality of Groß Pankow, went into regular operation in April 2017. The planning office Greenline from Flensburg is the general planner of the plant using input materials such as slurry, solid manure, and maize silage. The 8.5 megawatt biogas plant is operated by the biogas division of the technical contractors Osters & Voss from Wittenberge in the district of Prignitz.

Building on the existing 800 kilowatt biogas site which went live in 2014, the plant has been expanded further and focuses predominantly on a mix of cattle slurry and energy crops. The raw biogas is converted into bio-natural gas using physio-organic washing processes and then fed into the regional natural gas network of the Brandenburg utility company, E.ON-E.DIS.

All in all, the expanded plant now processes approximately 70,000 tonnes of slurry, 50,000 tonnes of maize silage, and 7,000 tonnes of solid manure. In turn, around 75 million kilowatt-hours of gas and heat are generated from these materials. In real terms, this volume supplies heat and electricity to approximately 16,000 households.

To this end, three fermenters and two secondary fermenters with a fermenting volume of around 23,000 cubic metres in total have been installed at the biogas plant as well as six digestate storage tanks with a holding capacity of around 42,000 cubic metres. A pump line measuring approx. two kilometres in length ensures the efficient and ecological transportation of substrates, the slurry is delivered by a dairy farm directly to the biogas plant.

“With this layout, this biogas plant ranks among the largest in Germany in tank volume and gas production, particularly setting functional and operational benchmarks,” emphasises Greenline Managing Director, Frank Nielsen.

“High quality, low production and operational costs, and a high degree of automation in new construction and flexibilisation projects are all helping to establish biogas production as the standard energy alternative in the market of regenerative energy sources going forward,” adds Nielsen. In particular, thanks to the latest EEG amendment and the modified framework conditions for approval, efficient planning concepts and low building costs are fundamental to the chances of executing biogas projects. Furthermore, waste plants for foreign markets with CO2 certificates are becoming increasingly more important. Here too, competitive kWh generation throughout the operational period plays a decisive role.

Information Request Email: mailto:info@pr-schulz.de Top